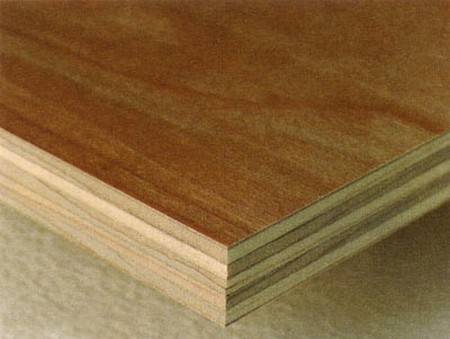

Plywood is made of thin sheets of wood joined together with various grades of glue. The thin sheets (veneers) are usually peeled from around a log, so they can be obtained in very large sizes. The grain in alternate sheets runs along and across the board which means that plywood behaves more uniformly than natural wood. Plywood always has an odd number of veneers to create a balance of glued surfaces and keep twisting and warping to a minimum. The grains of the surface veneers always run in the same direction. The thinnest boards are 3-ply; a thicker board might simply have thicker layers, or it might be a multi-ply with up to 11 layers.

Plywood is a remarkably versatile material and can be used to make virtually anything. It can be used outdoors to make Wendy houses, paddling pools, garden furniture, sheds and so on and indoors it can be used to make anything from shelves to wardrobes. On a grander scale, it can be used as a building material for houses, roofs, ceilings, extensions, stairs and walls.

Types of plywood

Plywood is imported from many different countries and there are different grading systems according to the quality of the surface veneers and the glues used in its manufacture.

The veneers may be described by the letters A, B or BB. A-veneers (the best quality) are rare, and most plywoods you are likely to come across will be B or BB. B-grade may have small knots and markings and may also have joints; BB-grade may have knots, plugs to fill knots, joints, discoloration and other faults. Often, a plywood board will have B-grade on one side and BB on the other and be labeled B/BB, but many boards will not be labelled at all.

Plywood is made with different glues for interior and exterior use. It may simply be described as ‘interior’ or ‘exterior’, but the most likely pointer towards the glue which has been used is found mainly on exterior-grade boards described as WBP weather and boil proof – which means it can withstand damp conditions, including outside. You may also find marine ply which uses WBP glues and durable species of timber.

The most common material used to face plywood is birch, and birch plywood is available in both interior and exterior grades. Other materials include redwood and whitewood (sometimes used together on opposite sides of the same board), sapele, oak and mahogany.

As well as wood veneer finishes, you can also get plywood with a variety of special finishes, including paint, plastic laminate and plastic facing (for wall-boards) among others.

The standard size of plywood board is 2440mm by 1220mm, which like many other board sizes is based on the imperial sizes 8ft by 4ft. Other, smaller sheets may also be available from 610mm square.

Typical uses for plywood include shuttering for concrete, furniture and drawers.

Working with plywood

Bending Plywood bends most easily at right-angles to the direction of the grain on the surface veneers. Thin plywoods can be bent without wetting or steaming. Thicker curved sections can be built up by bending and gluing thin plywoods together. If the plywood has to be dampened to bend it, make sure that it is completely dry before gluing.

Cutting Before cutting, the surfaces should be scored on both sides with a marking knife to reduce the likelihood of chipping the surface veneers. Thin plywoods – 3 to 6mm – can be cut easily with a tenon saw; thicker plywoods – 6 to 18mm – should be cut with a panel saw (or power saw). The saw should always cut through any decorative surface when using an electric jigsaw the plywood must be cut with the backing surface uppermost (jigsaws cut on the up stroke).

When drilling, place a piece of softwood beneath the plywood to prevent chipping as the drill bursts through.

The edges of plywood can usually be planed fairly easily as long as the plane is used from the corners to the middle to prevent splitting.

Fixing Plywood can be glued and lakes nails, pins and screws well.

When using glue, for maximum stability make sure that the grains of the surfaces to be glued lie in the same direction. Roughen the surfaces to provide a good key for the glue, spread the glue evenly and bring the boards together applying an even pressure. Use a waterproof glue for exterior work.

Always drill a pilot hole for screws and pins to reduce the likelihood of surface veneers tearing and lifting. Use screw cups to prevent heads sinking into the veneer. Plywood will often split if pins or screws are driven into the edge.

Finishing Plywood can be finished with paint, varnish or plastic laminate. Both surfaces of the plywood should be finished in the same way to avoid distortion. Plywood can be edged with softwood, hardwood, metal or plastic stripping all are best fixed with glue. Edges can also be filled and painted.

Surfaces for painting should be clean, smooth and free from grease. Edges should be smoothed and filled – an oil-based wood filler will probably produce the best finish. Plywood for use indoors can be primed with an ordinary wood primer, but for outdoor use an aluminium wood primer is preferable.

Two or more clear coats of polyurcthane varnish produce a good finish – all coals, bar the final one, may have to be rubbed down with wire wool. Wax polish can be used to achieve a very fine finish. Plywood, especially birch, can be stained before varnishing plain colours are very effective.